Research and development of new technology

Acquisition of patent

Ibaraki University-launched Venture Company of M&M Research Institute, in cooperation with metal Nano-particle paste by laser sintering, a metal film forming technology research and development.

HLPTM (points plating) is Harmful effluents, and waste liquid associated with clean and environmental friendly with new plating technology.

※HLP is a registered trademark of M & M Research Institute.

As one of the achievements, in June 2015, the patent of "a method and an apparatus for manufacturing a metal film forming method and a metal film-forming product" has been accepted registration.

| Inventive method | A method and an apparatus for manufacturing a metal film forming method and a metal film-forming product |

|---|---|

| Patent number | Pat.No.5760060 |

| Filing date | September 27, 2013 |

| Registration Date | June 12, 2015 |

Unique technology

HLPTM (point plating)(Show details PDF file)

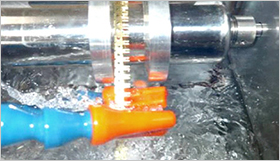

The metal nanoparticle paste is sintered with a laser, it is a unique technique for forming a metal film.

Feature

- Conservation of resources and limited range plating

- Only where needed (small size :Φ0.2mm ~ 0.8mm thickness of 0.1μm ~ 0.6μm range accuracy ± 0.1mm) I can processing of plating. Because it does not plated unnecessary portions, thereby saving expensive noble metal material.

- Stainless direct plating

- On a raw material for forming a passivation film such as stainless steel, having good adhesion gold plating is available for processing without the base plating, such as nickel.

- Inline plating

- Conventional is done has been carried out in a separate step as "pressing" and "plated" in-line. For processing in the same step, and excellent productivity.

- Low environmental impact

- In conventional electroplating methods, pre- treatment requires special chemicals, waste water treatment comprising them will be a challenge. HLPTM (point plating) because it does not require special chemicals in the pretreatment, it does not cause waste fluid. Load on the environment is small, it is ecological technology.

Specification

| Item | Specification | Remarks |

|---|---|---|

| Processing range | Φ0.2mm~Φ0.8mm | Plating processing to a wide range is impossible |

| Plating film thickness | 0.1μm~0.6μm | |

| Range accuracy | ±0.1mm | |

| Plating varieties | Gold , silver | |

| Workpiece material | Phosphor bronze, brass, copper, stainless steel | Stainless steel, plating can be processed without a base plating |

| Surface treatment | Nickel 0.3μm~1.5μm | |

| Primary use | Electrical contacts, solder joints, bonding pad |

Go back to the top of the page

HLP high speed laser plating TM device HLP-DCL100

(Show details PDF file)

The metal nanoparticle paste is sintered by the laser, and is a device for forming a metal film.

It applied only where needed, I can to minimize the material consumption for possible deposition.

This enables film formation to a substrate such as copper thermal effect is large in the conventional furnace firing.

Feature

- On-demand film forming apparatus of the laser sintering method.

- Including standard steel, it can be deposited on a wide range of metallic materials.

- It can be processed in the air and an inert gas atmosphere.

- Comfortable user interface that can be manipulated on the touch panel screen.

- By the process monitoring, enabling efficient experiment.

- Compact desktop design.

Specification

| Item | Specification |

|---|---|

| Plating type | Gold, silver (gold, use silver nanoparticle paste) |

| Material | Metal material in general including copper, copper alloy |

| Loading weight | 1kg |

| Processing range | 100 (W) ×100 (W) ×45 (H) mm |

| Stage movement speed | 50mm/秒 (Max) |

| Heater temperature | 150℃ (Max) |

| Laser output | 100W (Max) |

| Laser wavelength | 915mm |

| Laser focus diameter | 600μm |

| Defocus amount | ±15mm |

| Dimensions(body) | about 900 (W) ×550 (D) ×800 (H) mm |

| Dimensions(Control part) | about 600 (W) ×550 (D) ×800 (H) mm |

| Body weight | about 80kg |

| power supply | AC200V 50/60Hz |

Go back to the top of the page

Auto multifaceted measuring instrument(Show details PDF file)

Product is automatically measured from the four directions that you set, and then report the high-precision measurement results.

Feature

- Since the measurement from four directions of the product is performed automatically, enabling high-precision measurement without desorption.

- By saving the image data, it can be re- validation of past product.

- It has a reference calibration,

by monitoring changes in the measurement, and realize stabilization of the measurement results. - It realizes the depth of focus by the high-performance lens, capable of preventing defocus of irregularities, to obtain measurement results of high accuracy.

- Measurement is performed after the completion of the process of trend analysis, and carried out the anomaly detection process immediately.

- Since the measurement error due to manual work is reduced to a low level, capable of high-precision measurement of equivalent to the inspectors also in the field workers.

- Since the measurement record is saved automatically, and reduce the work load, such as manual input.

- If a network environment, it viewable measurement data from another PC terminal in the network.

- Measurement of one product is completed in about 1 minute. (From the product set to the measurement data output)

Go back to the top of the page

Inline image inspection apparatus Ver2(Show details PDF file)

Was introduced on the line, do the automatic measurement and inspection by the image sensor.

Feature

- 19 monitor is easy to see.

- It can be installed in a narrow space.

- It can be installed in the automatic winder in the separation type.

- Winder is possible in the longitudinal feed.

- Possible without inspection that twisting.

Go back to the top of the page

Hoop product cleaning equipment(Show details PDF file)

The product or the like which is output from the press machine, and is performed continuously by washing remains hoop state.

Feature

- Us, regardless of the carrier position (front-back) by its own guide roller, and realize that to feed the hoop goods always stable condition.

- Easy operation, the installed all-in package that can be used on the day.

Go back to the top of the page

Automatic two consecutive winding winding device(Show details PDF file)

The product or the like which is output from the press machine, and wound up by tuning the feed rate.

Feature

- Tuning winding to launch speed of the press.

- Automatic sampling (up to 150mm) automatic winding function.

- During the Paste one push extra winding function paper.

- The remaining winding function the paper between by the number of seconds specified.

- Entrainment auxiliary function.

- Easy to install our in-line image sensor.

Go back to the top of the page